Payment Type:L/C,T/T

Incoterm:FOB,EXW

Min. Order:1000 Piece/Pieces

Transportation:Ocean,Land,Air,Express,Others

Port:Shanghai

Model No.: 304/316/other

Brand: JUKE

Surface Treatment: Plain

Place Of Origin: China

Structure: Welded Chain, Chain Wheel, Combined Chain, Combine

Features: Transmission Chain, Drag Chain, Tyre Protection Chain

Is It A Standard Part: Standard, Nonstandard

Packaging: Pallet

Productivity: 500Tons/Month

Transportation: Ocean,Land,Air,Express,Others

Place of Origin: Taizhou,China

Supply Ability: 200 Ton/Month

HS Code: 73158200

Port: Shanghai

Payment Type: L/C,T/T

Incoterm: FOB,EXW

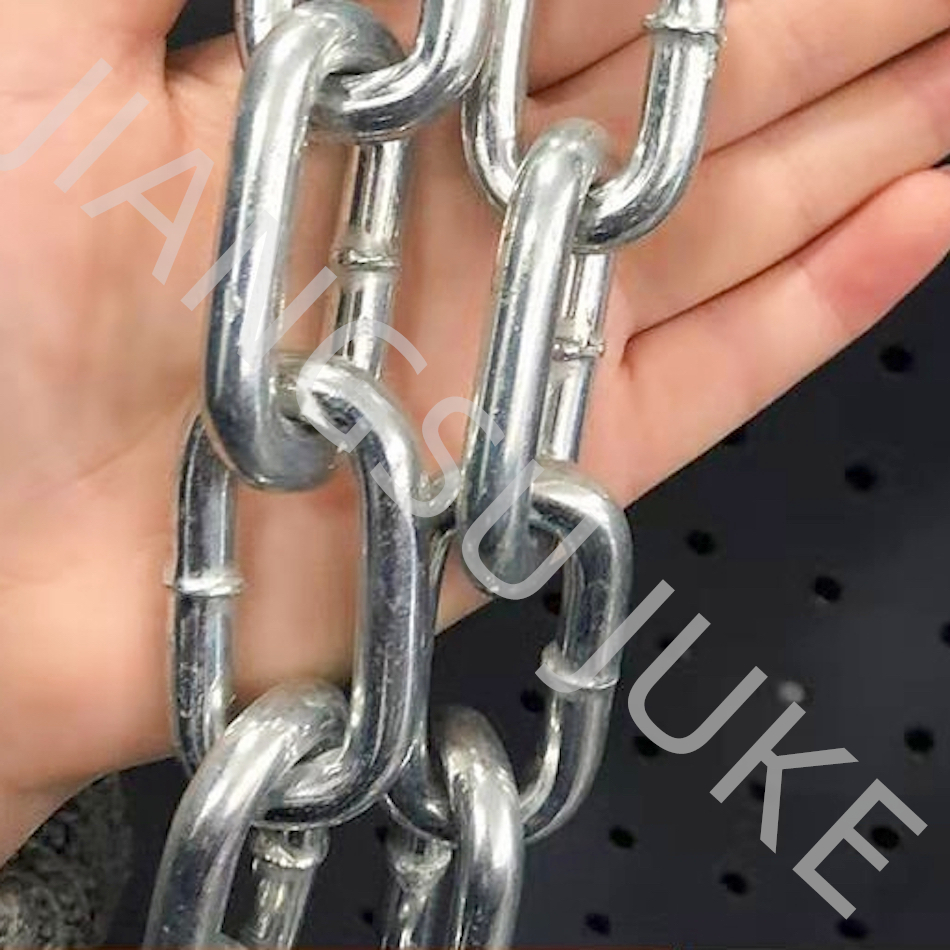

Long Stainless Steel Chain Zinc Plating

Surface treatment: Electric galvanized link chain, hot dipping galvanized link chain, zinc plated

Usage: Lashing, transportation, transmission, construction, fence, shop decoration, swing, fishing, lifting chain, hardware chain, anchor chain, snow chain, animal chain, elevator balance chain etc.

Type: Ordinary mild steel link chain, short link chain, medium link chain, long link chain

Size:3mm to 28mm

Jiangsu Juke Metal products Co., LTD can offer Short Steel Link Chain no burr chain, Stainless Steel Link Chain, Stainless Steel Din Long Link Chain, Stainless Steel 304 Welded Link Chain.

Q1: What is long stainless steel chain with zinc plating?

A1: Long stainless steel chain with zinc plating refers to a type of chain made from stainless steel material that has been coated with a layer of zinc for added protection against corrosion and improved aesthetics.

Q2: What are the benefits of using long stainless steel chain with zinc plating?

A2: The zinc plating on the stainless steel chain provides enhanced resistance to rust and corrosion, making it suitable for outdoor applications or environments with high moisture levels. Additionally, the zinc coating gives the chain a shiny and visually appealing appearance.

Q3: What industries or applications commonly use long stainless steel chain with zinc plating?

A3: This type of chain is commonly used in various industries such as marine, construction, agriculture, and transportation. It is ideal for applications that require durability, strength, and resistance to corrosion.

Q4: What lengths and sizes are available for long stainless steel chain with zinc plating?

A4: Long stainless steel chain with zinc plating is available in various lengths and sizes, depending on the specific requirements of the application. Common sizes range from small diameters suitable for lightweight applications to larger diameters for heavy-duty purposes.

Q5: Can long stainless steel chain with zinc plating be cut to custom lengths?

A5: Yes, long stainless steel chain with zinc plating can be cut to custom lengths to meet specific project requirements. This can be done using appropriate tools and techniques.

Q6: How should I maintain and clean long stainless steel chain with zinc plating?

A6: To maintain the appearance and performance of the chain, regular cleaning is recommended. Use a mild detergent or soap with warm water to remove dirt and grime. Avoid using abrasive cleaners or brushes that may scratch the zinc plating.

Q7: Can long stainless steel chain with zinc plating be used in saltwater environments?

A7: Yes, the zinc plating on the stainless steel chain provides an additional layer of protection against corrosion, making it suitable for saltwater environments. However, periodic rinsing with fresh water and proper maintenance are still recommended to prolong its lifespan.

Q8: What load capacities can long stainless steel chain with zinc plating handle?

A8: The load capacity of the chain depends on various factors such as diameter, grade, and configuration. It is important to refer to the manufacturer's specifications and guidelines to determine the appropriate load capacity for your specific application.

Q9: Are there any safety precautions to consider when using long stainless steel chain with zinc plating?

A9: When working with any type of chain, it is essential to follow proper safety procedures. This includes wearing appropriate protective gear, ensuring proper installation and attachment, and regularly inspecting the chain for any signs of wear or damage.